34CrMo4 Thin Wall Thickness Seamless Steel Tube for Gas Cylinder

34CrMo4 Alloy Seamless Steel Pipe We are supplying thin wall thickness seamless steel pipe by material 34CrMo4. This kin;

Basic Info

| Model NO. | 34CrMo4 seamless steel tube |

| Outer Diameter | 60mm~416mm |

| Wall Thickness | 3.5mm~10mm |

| Length | Fixed Length, by Random |

| End Processing | Bevel Ends, Plain Ends |

| Transport Package | Standard Seaworthy Packing |

| Specification | ASTM A213, A312, etc |

| Trademark | Iron&steel |

| Origin | China |

| HS Code | 73045910 |

| Production Capacity | 1000ton Per Month |

Product Description

34CrMo4 Alloy Seamless Steel PipeWe are supplying thin wall thickness seamless steel pipe by material 34CrMo4.

This kind of pipe is widely used for making gas cylinder

The manufacturer is TPCO and Baotou steel company, which is the most famous manufacturer of seamless teel pipe

Standard: ASME SA106, ASME SA335, ASME SA333, DIN17175, EN10216-2, GB5310, GB3087.

Steel grade: 34CrMo, 37Mn, SA335 P11/P12/P22/P91/P92, WB36, 10CrMo910, 20G, 15CrMo, 12Cr1MoVG,

SA333 I, SA333VI, ST45.8/III,etc

Outer diameter:88.9mm~416mm

Wall thickness: 4mm~10mm

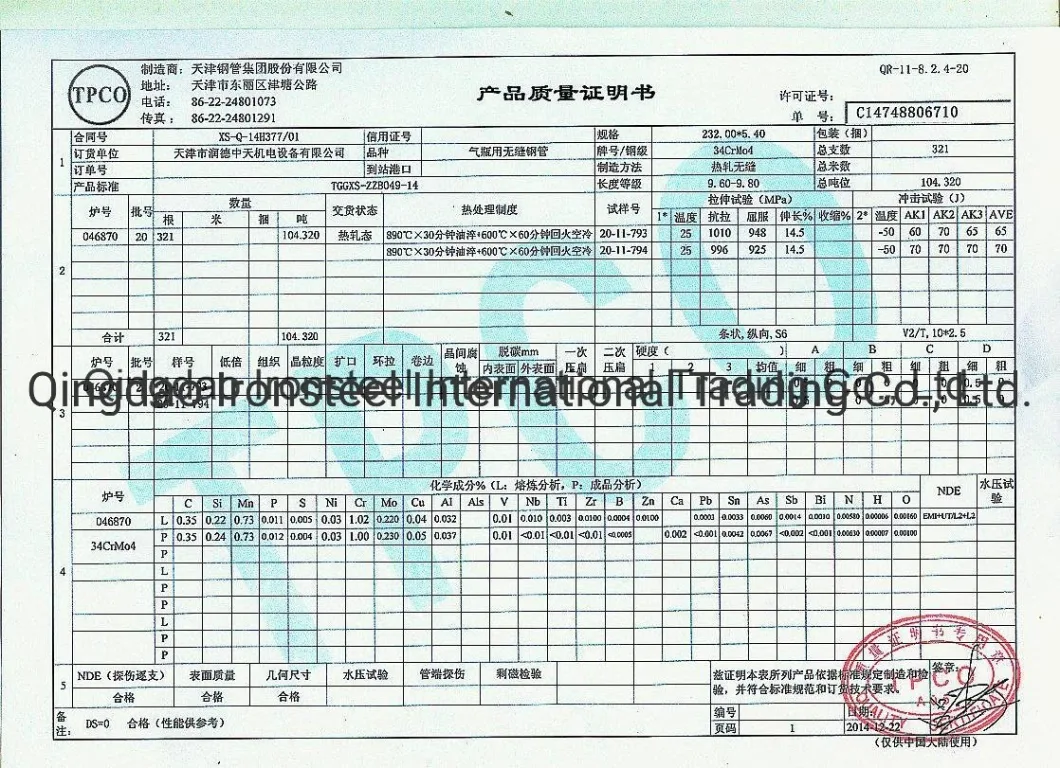

MTC of 34CrMo4

Tolerance of size of our seamless alloy pipe:

| Type of pipe | Outer diameter | Wall thickness | ||

| OD (mm) | Tolerance (mm) | WT (mm) | Tolerance (mm) | |

| Hot rolled pipe | 60~416 | ±10% | 3.5~10 | ± 20% |

Our service

Make production according to customer's specific requirements strictly.

Accept inspection during the production or before shipment.

Provide the original copy of MTC(Mill testing certificate)

Provide the standard seaworthy packing.

Arrange the most professional shipment.

You may also like

Send inquiry

Send now